6 reasons to print with PEEK Polymers

And an introduction why this is not difficult

What is PEEK 3D Printing?

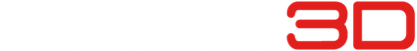

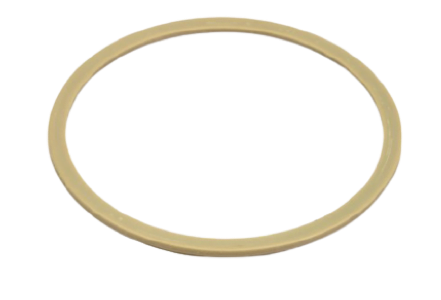

PEEK 3D printing is the process of using a 3D printer to create objects using PEEK (polyetheretherketone) as the print material. PEEK is a high-performance polymer that offers exceptional strength and thermal stability, making it ideal for use in a wide range of applications. 3D printing with PEEK allows users to create complex, custom-designed parts and objects with a high degree of precision and accuracy.

To print with PEEK, a spool of PEEK filament is loaded into the Bond3D 3D printer, which then melts the filament and deposits it layer by layer to build up the desired object. The Bond3D printer can is controlled by our in-house developed software, which allows us to create a digital model of the object and specify the desired dimensions and other parameters. The 3D printer then follows the instructions to create the object.

Overall, PEEK 3D printing offers many advantages, including the ability to create complex and custom-designed objects, rapid prototyping, and the ability to produce parts and objects with high precision and accuracy.

Resources

6 advantages of using PEEK as a material for 3D printing

There are several advantages to using PEEK (polyetheretherketone) as a material for 3D printing. Some of the key benefits of printing with PEEK include:

Is printing with PEEK polymers difficult?

The ease of printing with PEEK (polyetheretherketone) depends on several factors, including the type of 3D printer being used, the quality of the PEEK filament, and the experience of the user. PEEK is a high-performance polymer that can be difficult to work with, and it requires a special developed 3D printer with a heated bed and an enclosed build chamber to prevent warping and other issues.

Furthermore, PEEK filament can be expensive and may require special handling and storage to prevent degradation. As a result, printing with PEEK is typically more challenging than printing with other materials, such as PLA or ABS. However, with the right equipment and expertise, it is possible to achieve high-quality prints with PEEK by leveraging our technology.