Unlock the full potential of 3D Printing with PEEK

The amount of 3D Printed Functional parts is growing rapidly. Still there are a lot of companies that don’t realize the potential of 3D Printing with PEEK in their everyday business. We would like to give you more guidance about the printing process by giving a detailed overview of the steps involved.

Additive manufacturing is changing the way how high-tech companies in the the energy, electronics, automotive and medical industries. The strength and low-weight PEEK 3D printing material is helping companies to replace metal parts to polymer parts. PEEK is also used in critical application by creating rapid prototypes and to create a better time to market with lower costs. Bond3D is specialized in supporting high-tech companies in changing the rethinking engineering and manufacturing in 3D PEEK Printing.

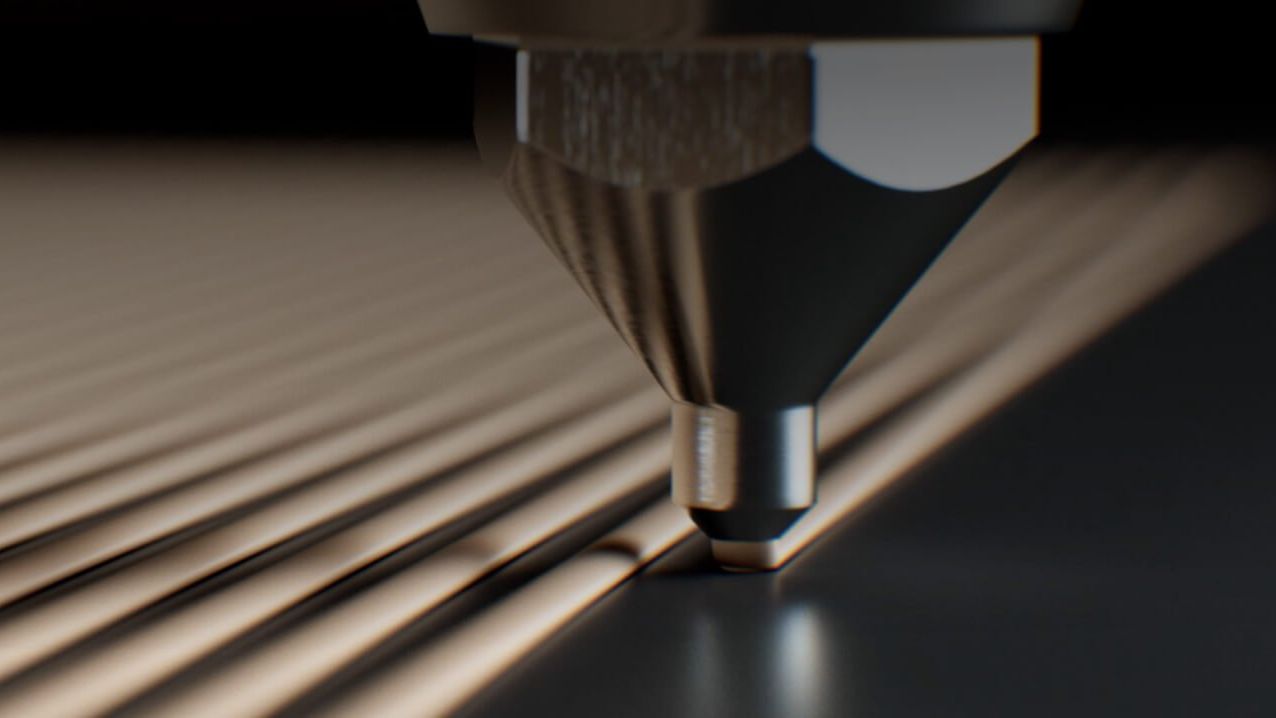

Software- and printing technology

At Bond3D, we developed our unique printing technology completely in-house, including system mechatronics, software, slicing technology, and process validation. Every part in the process is optimized to deliver the best possible result. Our engineers are constantly adjusting all steps and details in the processes to print superior PEEK 3D printed parts.

The proces from product design to large series production

In close cooperation with our design & engineering team we will follow a process that can be summarized in three big steps: product design, prototyping and production.

Product design

The first and far most important step is all about designing your product. Together with our design and engineering team you will do a deep dive to determine the features of the 3D Printed product. We will not be working with a physical prototype yet and most of the work will be done in our in-house developed software.

Concept generation

Before we can start printing we need to come up with the best possible solutions. Usually, there is a clear idea of what to create but with the characteristics of PEEK there is the possibility to go a step further and create the perfectly printed PEEK product. In collaboration with our design and engineering team, we can create a concept that matches all the needs for you and your processes.

Typically, these steps mean coming up with a list of ideas to solve the problems you are addressing combined with our knowledge.

Materials for 3D Printing

When designing complex parts for demanding applications, you want to have the best of both worlds. A material of superior quality and the design freedom offered by additive manufacturing, or 3D printing, to achieve optimal functionality.

For good reasons, PEEK may be the material of your choice, but up till now, this came with a downside. Printing PEEK is far from easy, because of its high viscosity in the molten state and its semi-crystalline nature, which induces shrink upon solidification. A common reflex of process developers then is to adapt the material to the available printing technology.

At Bond3D, we decided to follow the reverse strategy and adapt the process to the material, to preserve its favorable properties in printed products. In principle, this could be any material, but we put the focus on high-performance polymers PEEK.

Design for PEEK

Now the biggest changes are seen between the traditional machine processes and 3D Printing. And there is even a difference between regular FDM printing and printing with PEEK. Printing with PEEK gives the possibility to create personalized, lightweight and functional designs that are matched with your product development lifecycle. We will search for the best possible cohesion between the parts that need to be created and how we can utilize the characteristics of PEEK.

Tolerance specifications

PEEK has a lot of characteristics that make it suitable for every industry. With our technology, we are able to print voidless parts that are isotropic in strength. Also, PEEKS offers electrical insulation, manages extreme temperatures and is chemical resistant.

Prototyping

After all previous steps are taken it’s time to start printing. This phase is all about getting printing, testing and redesigning. The parts that we print in this phase are not the final products but will give you the right insights and answers for the production phase.

This is the phase to really show the capabilities of our technology and PEEK. We can quickly print, test, re-design and re-print prototypes to create the perfectly printed PEEK parts.

Proof of concept

The main reason to create a prototype is to prove the concept. Many of our customers and partners are creating 3D Printed parts for the first time or only have experience with regular 3D Printing. Also, computer-generated models will not give you all the information that is needed to evaluate a prototype.

Testing

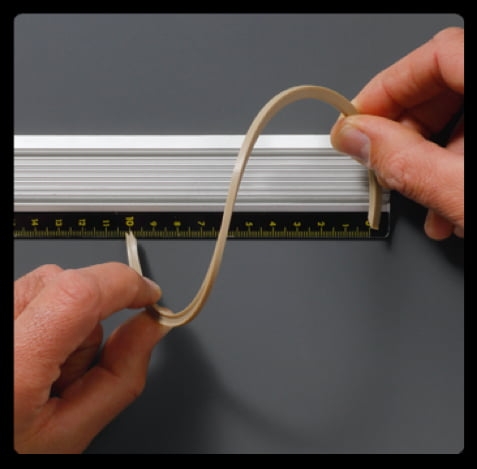

Our prototypes can be tested in different forms. Of course, this can be done by a physical limit test to see how strong the parts are. But we are also able to test the parts in a pressure burst test or pull/flex /compression test. If needed, we can set up specific tests that are needed for your particular industry. And if you want to break some parts to see their limits? That’s no problem as we can quickly print some new prototypes within a short timeframe.

Re-designing

After testing we collect all the results to see where we need to improve our designs. This will be done in the redesigning phase where we will adjust the prototype based on all the information and restart the testing process. If needed, we will start from scratch if we need to find a new solution.

3D Printers give us the opportunity to quickly execute changes so we can iterate on small changes without any problems. It doesn’t matter how small or big the redesign is.

Production

The last phase in our process it the production of the (re-)designed and tested parts. Now it’s time to make a final product that’s ready to be used in your critical applications. The Bond3D design and engineering team will create an approach how we can produce your parts in series when needed.

All our PEEK 3D printed parts have a short time to market. When necessary we can create a digital stock for you.

Post-processing

Our 3D Printed PEEK parts will get the right post-processing to add the finishing touch to our parts so it’s ready to use. This means that we will smoothen the surface and edges, add extra dimensions and make sure all tolerances are optimal.

Production of series

Printing with PEEK is highly suitable for printing parts in critical applications. Our design and engineering team can create the perfect single part for a specific use but we are also able to print bigger series. All our products can easily be printed in series with a short time to market. We also offer the possibility to have your products in digital stock so they can be printed on demand.

Final quality assessment

All our parts will get a thorough assessment of their quality. This ensures we deliver the right parts with the right characaristics and we limit the delivery of defective parts.

Talk to us

We believe transforming manufacturing is a team effort. Let’s get in touch and discuss how we can help you take the next step.