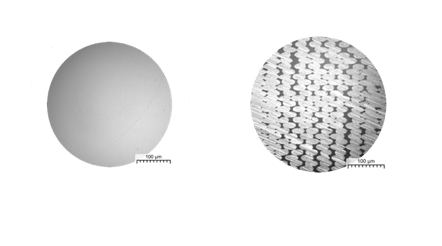

High tensile strength resulting from patented solution to produce parts virtually free of voids

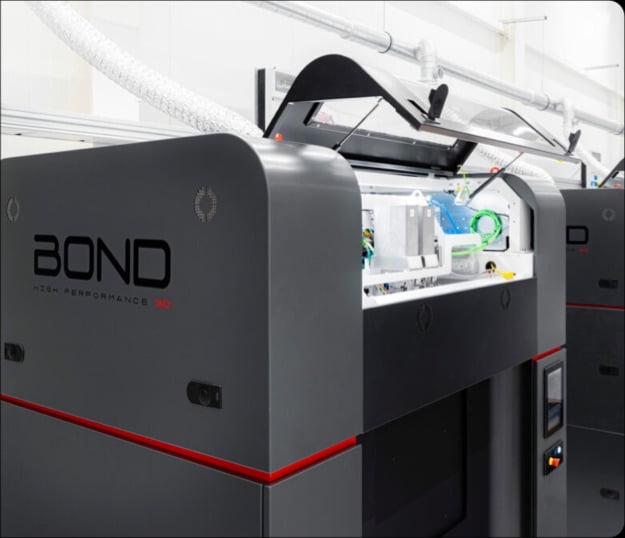

High-performance polymers, such as PAEK, are used for many critical applications in the medical, automotive, aerospace and other industries with conventional manufacturing technologies (injection molding, extrusion, CNC machining). Bond3D is the first company in the world that is able to print functional products from high-performance polymers without losing the inherent characteristics of the material. As a result, Bond3D is unique in its ability to produce functional parts that are certified for use in critical applications, which no competitor has been able to accomplish in a meaningful way. In addition to replacing production of prototypes, tools and functional parts currently manufactured from metal and for FDM, PEEK 3D is a low volume-high capital addition to conventional manufacturing technologies of PEEK.

Bond3D offers a superior manufacturing alternative

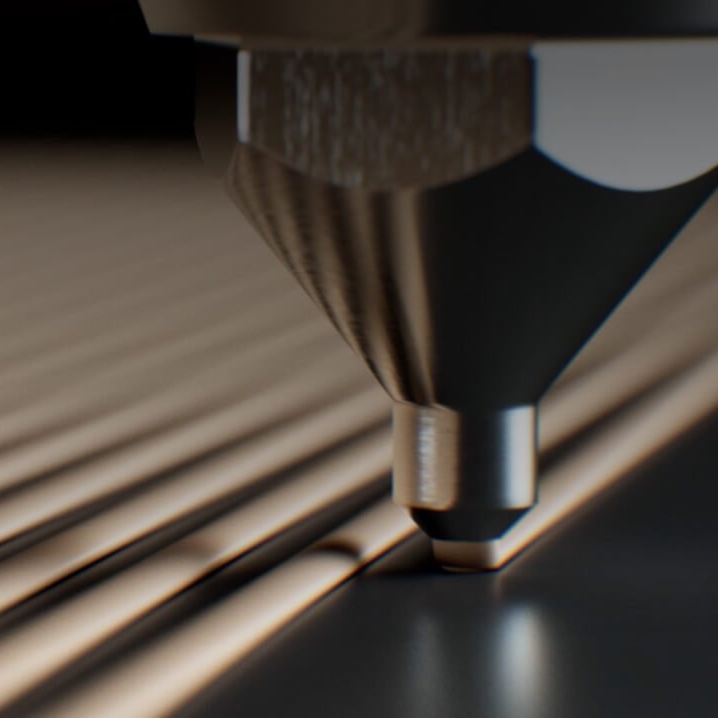

- Free forming capabilities allowing complex shapes, pressure tightness, virtually free of voids

- Alternative to metal: weight reduction, corrosion resistance and spark-proof

- Easier, faster and cheaper than powder metal printing, injection moulding or casting

- Significant reduction of total production costs

- Low batch start-up costs and time

- Ease of use and high manufacturing reliability

- 8x times material reduction against PEEK machining

Bond3D has adapted the printing process to the material instead of manipulating the material to make it printable.

With Bond3D’s unique technology

- It is possible to seamless manufacture highly complex and customized structures in small series production

- Initial costs, set-up time, unit cost price and total production time of single products and small series are lower

- It is possible to create products with less components, lighter weight and less waste