MEET BOND3D

AT FORMNEXT 2022

Ready to rethink the engineering

and manufacturing in 3D PEEK Printing?

Perfectly Printed PEEK Products at Formnext 2022

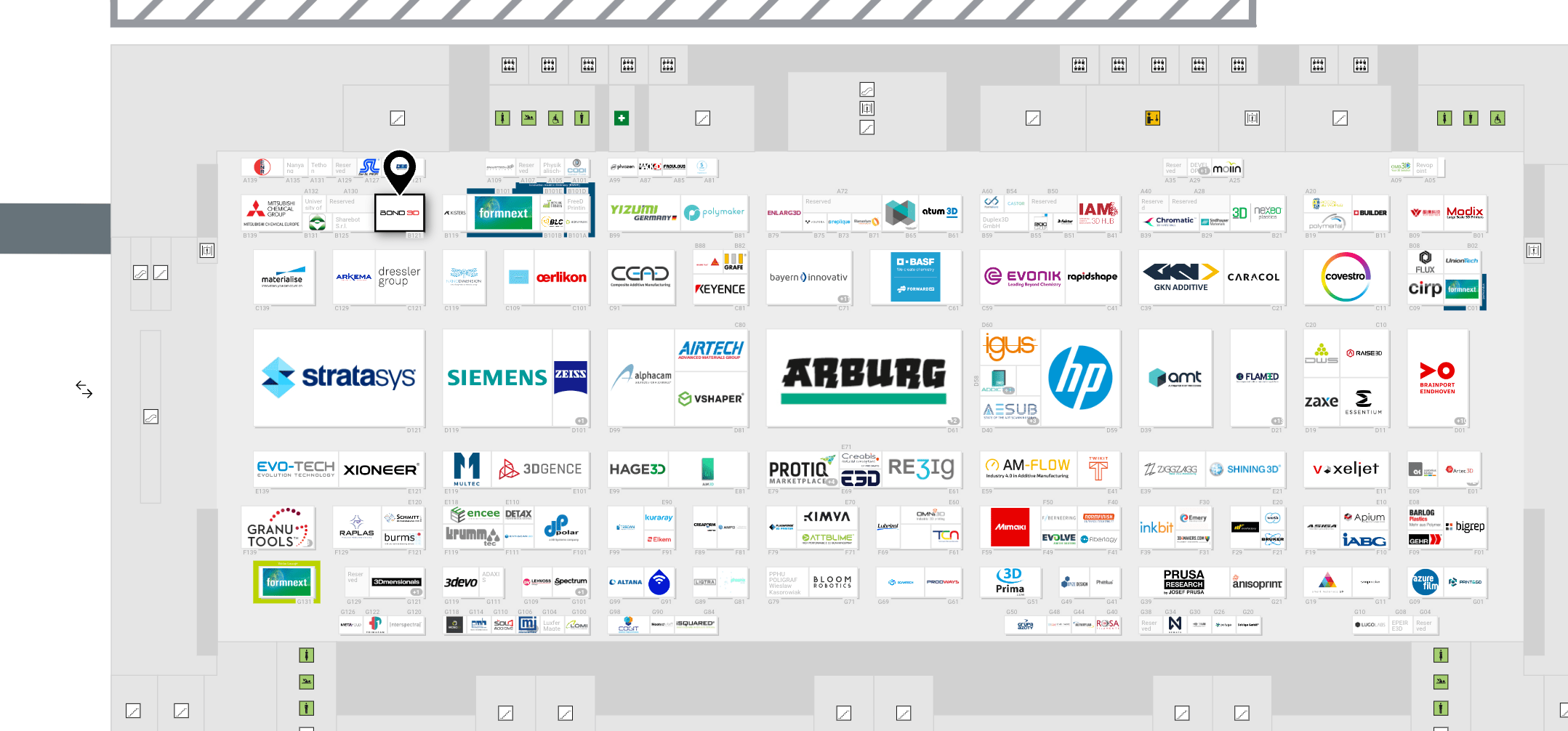

Formnext 2022, the most important event for the additive manufacturing industry, will welcome participants from 15 to 18 November at Messe Frankfurt for its eighth edition. Formnext 2022 will bring together visitors and exhibitors from the AM community for a live event showcasing the latest innovations, manufacturing methods and software solutions in the business.

Bond3D will attend the event as an exhibitor to discuss your challenges to create Perfectly Printed Peek Products.

Where to find Bond3D at Formnext

Where to find Bond3D at Formnext

Find us in hall 12.1 booth B121

Discover and see all our perfectly printed PEEK products and talk to our application engineers. Find Bond3D at hall 12.1 booth B121.

Join our workshop

Join our workshop

Thursday, November 17th | 15:30

Ready to upgrade your knowledge? Join our workshop: “Design For PEEK Additive” with our application engineering team. Just 30 seats available!

Join us for drinks

Join us for drinks

Thursday, November 17th | 16:30

Join us for drinks at Formnext on Thursday, 17th of November at 16.30.

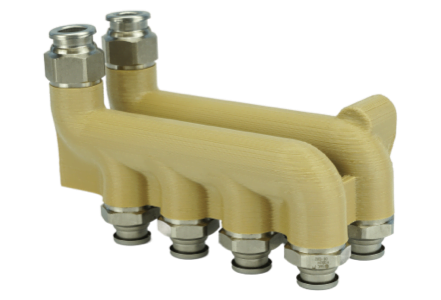

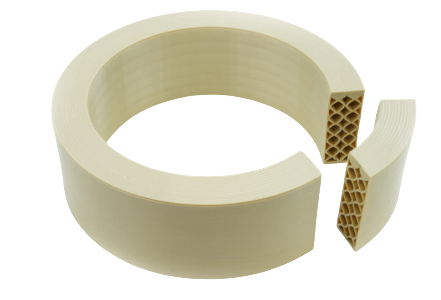

How PEEK parts can change your industry

Learn what our 3D Printed products can do for you

Critical parts made from PEEK

These parts can change your industry

About Bond3D

Bond3D High-Performance 3D technologies BV operates out of Enschede, the Netherlands. Since 2014 we have always been at the forefront of industrial 3D printing. Our patented technology is unique in its ability to produce functional parts from high-performance polymers that are certified for use in critical applications.

At Bond3D, we develop our unique printing technology completely in-house, including system mechatronics, software, slicing technology, and process validation. We change the conversation on engineering in medical, aerospace, energy, automotive, manufacturing, and engineering applications.

Where to find Bond3D at Formnext

Where to find Bond3D at Formnext

Join our workshop

Join our workshop Join us for drinks

Join us for drinks