A wafer holder, also known as a wafer chuck or wafer stage, is a device used to hold and support a wafer during various manufacturing processes in the semiconductor industry.

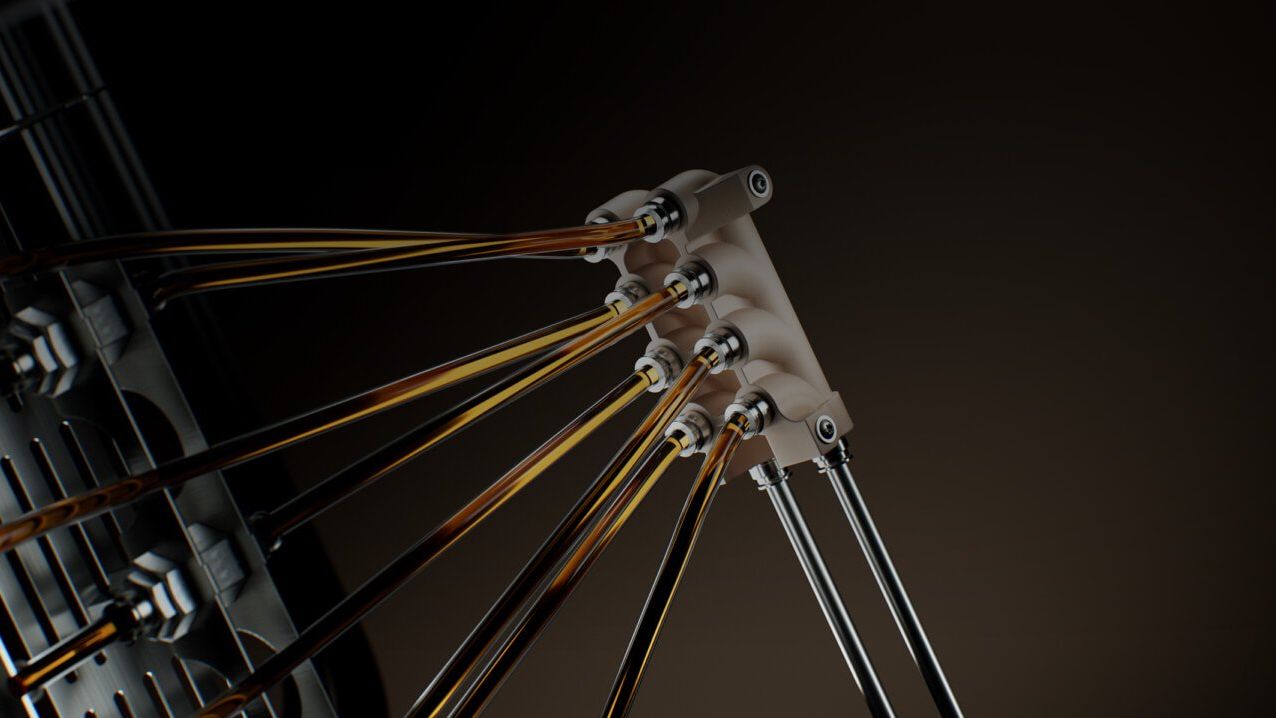

A 3D printed manifold is a component that is used to distribute, mix, or separate fluids or gases within a system. Manifolds are commonly used in various industries, including the automotive, aerospace, and chemical processing industries. They are used to connect and control the flow of fluids or gases within a system, and they may be used to distribute fluid or gas to multiple locations or to combine multiple fluid or gas streams into a single stream.

A 3D printed manifold is a manifold that is produced using 3D printing technology. 3D printing, also known as additive manufacturing, is a process of creating a physical object by building it layer by layer from a digital model. 3D printed manifolds can be made from a variety of materials, including plastic, metal, and ceramic.

3D printed manifolds offer several benefits compared to traditionally manufactured manifolds. They can be customized to specific design requirements, they can be produced more quickly and at a lower cost than traditional manufacturing methods, and they can be produced with complex geometries that may be difficult or impossible to produce using traditional methods.

3D printed manifolds are used in a variety of applications, including automotive fuel systems, aircraft fuel and hydraulic systems, and industrial process systems. They are used to distribute, mix, or separate fluids or gases within a system, and they may be used to control the flow of fluids or gases to specific locations or to combine multiple fluid or gas streams into a single stream.

Browse our other parts printed with PEEK

Wafer Holder

Spinal Cage

Spinal cages are typically made of a biocompatible material, such as titanium or a polymer, and are designed to be implanted into the spine to provide support and stability following a spinal fusion procedure.

Cranial implant (CMF)

Cranial implants are typically used to treat conditions such as skull fractures, defects resulting from trauma or surgery, or to correct abnormalities in the shape of the skull.