On-demand manufacturing allows a diverse amount of sizes te be manufactured in a short timeframe, to minimize downtime.

-

Chemical resistant

-

Minimale waste (no billet)

-

Digital stock & short TTM

-

Voidless printing

-

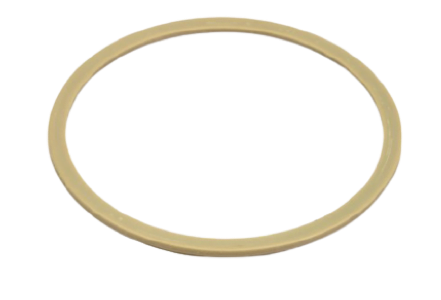

Custom developed wafer holder that’s chemical resistant. As milling is not an option, this part is 3D Printed with PEEK Polymers to reduce the amount of material and save weight.

-

Chemical resistant

-

Low weight

-

Inline printed

-

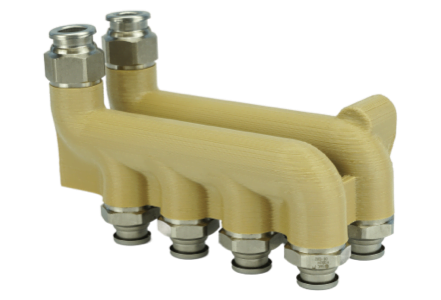

The semiconductor industry uses a variety of fluid manifolds, which are perfect for the Bond3D leak-tight technology and PEEK material.

-

Leak-tight manufacturing

-

Reduced parts

-

Low weight

-

Optimized flow

-

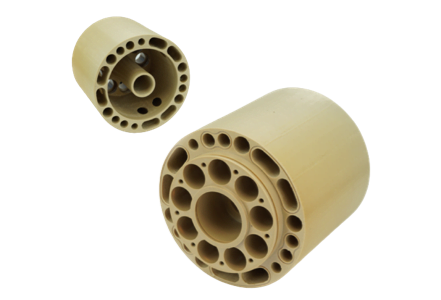

3d-printing PEEK opens up new possibilities for the Energy market. With our technology we can produce pump housings that are flow-optimized so no residue sticks in the channels due to the PEEK material.

-

Leak-tight manufacturing

-

Chemical resistance

-

Optimize flow

-

Metal replacement

-

Digital stock & short time-to-market

-

Cooling fluid is distributed by this flow-optimized manifold, simultaneously saving weight and enhancing production output.

-

Leak-tight manufacturing

-

Reduced parts

-

Low weight

-

Optimized flow

-