Isolating the phase cables from a 700V electric motor to the inverter. 3d-printing allows our customer to make last-minute changes in the prototype phase.

-

Leak-tight manufacturing

-

Reduce parts

-

Low weight

-

Flow optimization

-

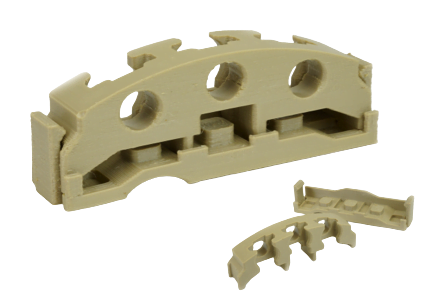

Optimizing battery systems using less parts and leak-tight PEEK cooling tubes.

-

Leak-tight manufacturing

-

Reduce parts

-

Low weight

-

Flow optimization

-

“Less is more”- using additive manufacturing, assemblies can be reduced to one integrated part.

-

Complex structures possible

-

Low weight

-

High strength

-

Function integration

-

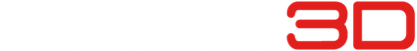

Amphenol PCD has asked Bond3D to develop the P75D clamp for additive manufacturing. Various sizes and design iterations can be quickly made without high setup costs.

-

Complex structures possible

-

Low weight

-

High strength

-

Function integration

-

The Peek spinal cages printed bij Bond3D offer superior properties compared to the Ti competitors.

-

One part production possible

-

Medical-certified material

-

Short lead time

-

Flexural modulus

-

Customized cranial implants can be produced using the Bond3D technology with less waste and faster times.

-

One part production possible

-

Medical-certified material

-

Short lead time

-

Flexural modulus comparable to bone

-

A buoyant part has been designed that actuates based on liquid level. The density and maximum load are optimizable with design.

-

Pressure resistance

-

Purity

-

Chemical resistance

-

Freedom of design

-

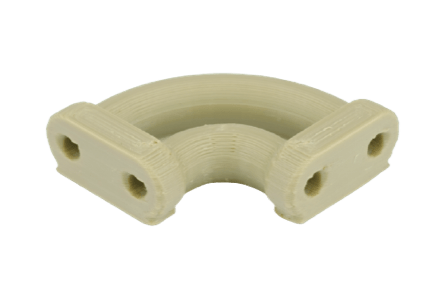

The insulating ring of the Bond3D machine has been optimized using a special 3D-infill type to improve the insulating properties.

-

Unique and complex designs

-

Reduced costs

-

Lower material usage

-

Enhanced insulating properties

-

The design freedom is large with 3D-printing. This static mixer uses the design freedom to optimize the mixing capabilities.

-

Complex structures possible

-

Strong parts

-

Design freedom

-

Function integration

-

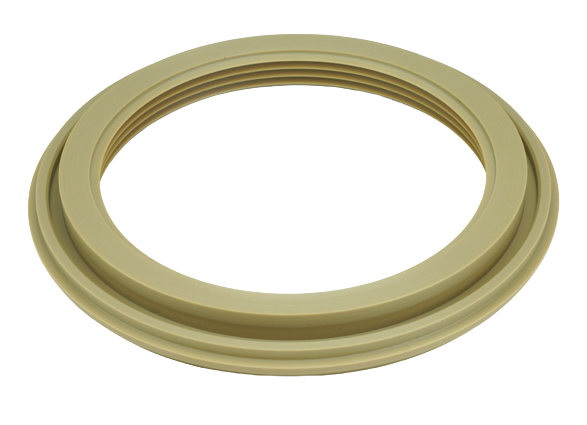

3D-printing makes it possible to print seals near-shape and finish the product to tolerances using conventional machining methods.

-

Chemical resistant

-

Minimale waste (no billet)

-

Digital stock & short TTM

-

Voidless printing

-