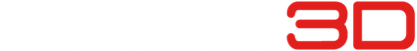

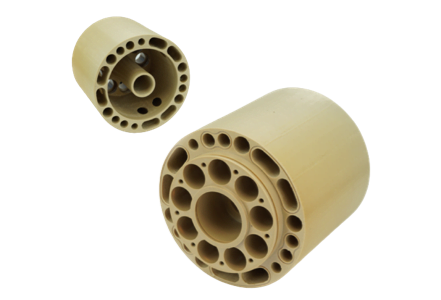

3D Printed PEEK parts and components for the energy industry

3D printed PEEK (Polyetheretherketone) parts are suitable for the energy industry for several reasons:

- High temperature resistance: PEEK is a high-performance thermoplastic that can withstand high temperatures, making it ideal for use in harsh environments, such as those found in the energy industry.

- Chemical resistance: PEEK is resistant to a wide range of chemicals, including corrosive and aggressive liquids, making it a suitable material for use in environments where chemical exposure is likely.

- Mechanical properties: PEEK has excellent mechanical properties, such as high strength, toughness, and stiffness, which make it a suitable material for use in energy applications where these properties are critical.

- Lightweight and low density: PEEK has a low density and is lightweight, making it ideal for use in energy applications where weight is a critical factor, such as in the aerospace or wind energy industries.

- Cost-effectiveness: 3D printing PEEK parts allows for the production of complex shapes and geometries at a lower cost compared to traditional manufacturing methods, making it a cost-effective solution for the energy industry.

In summary, the combination of high temperature resistance, chemical resistance, excellent mechanical properties, low density and cost-effectiveness make 3D printed PEEK parts an ideal material for use in various applications within the energy industry.