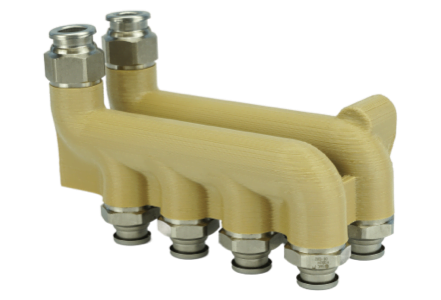

PEEK PARTS FOR EVERY INDUSTRY

Discover our Perfectly Printed PEEK Products

PEEK parts & Components

PEEK, also known as polyetheretherketone, is a high-performance engineering plastic with exceptional resistance to corrosive chemicals as well as superior mechanical strength and dimensional stability. It offers resistance to hydrolysis in sea water, water, and steam. PEEK is suitable for continuous use at temperatures up to 338oF and has the capacity to maintain stiffness at high temperatures (170oC). In demanding environments like semiconductor, energy, medial oil and gas, food and beverage processing, and aerospace, this engineering plastic has a proven track record.

Critical parts & components made from PEEK. Printed by Bond3D

PEEK components PEEK for every industry

PEEK’s exceptional electrical properties make it an ideal electrical insulator for various applications, including circuit boards, sensitive circuits, and hard drive disks. PEEK components also offer long-term reliability over a wide range of pressure, frequency, and temperature fluctuations, making it a reliable choice for demanding environments.

PEEK is a biocompatible material used in medical applications, including spinal implants and skull reconstruction. With strength and modulus similar to human bone, PEEK components are well-suited for such applications. Furthermore, PEEK components can withstand multiple sterilization cycles in a steam autoclave without any damage, making them reusable medical instruments. These properties make PEEK a valuable material for medical professionals looking for reliable, biocompatible materials.