HOW WE DESIGN WITH PEEK?

We help you to realize your idea to functional 3D printed PEEK parts

Designing for

PEEK Performance

The Design & Engineering department of Bond3D is there to support you in your journey of printing PEEK 3D Functional parts. Challenge our designers and engineers to create business impact by rethinking and manufacturing essential parts for critical applications. Our team of experts is highly trained and motivated to create personalized, lightweight and functional designs that are matched with your product development lifecycle.

How to design for PEEK

We help you to realize your idea by leveraging our expertise in PEEK 3D Printing. Our design and engineering team will search for the best possible solution to create the best possible cohesion between your application, production and how to utilize the characteristics of PEEK.

We are here to add value to your applications with high-end products with fewer components, less weight, and less waste. For the first time, printed parts are certified for use in critical applications.

Why choose PEEK?

Excellent wear properties

Electrically insulating

Easy post-processing

Extreme temperatures

(-40°C to +250°C)

Mechanical strengths

(TS 98 MPa)

Chemical resistance

(also sterilization by Gamma)

Bio inert

(also radiolucent for X-ray, CT or MRI)

High purity

Why we design and print with PEEK

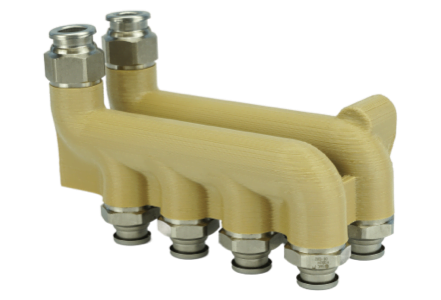

PEEK is recognized as one of the strongest and chemically resistant polymers, which is capable of replacing metal. It’s a colorless, organic thermoplastic polymer that achieves some of the best results out of all thermoplastics available worldwide, is therefore seen as a high performance polymer.

PEEK has a broad range of unique qualities and is therefore a very interesting choice for a number of different industries. In the semiconductor, oil and gas and the automotive industry PEEK is already the material of choice to 3D Print functional parts. It’s therefore the perfect solution for low-volume production and specialist designs where it’s difficult to create prototypes using metal and traditional techniques.

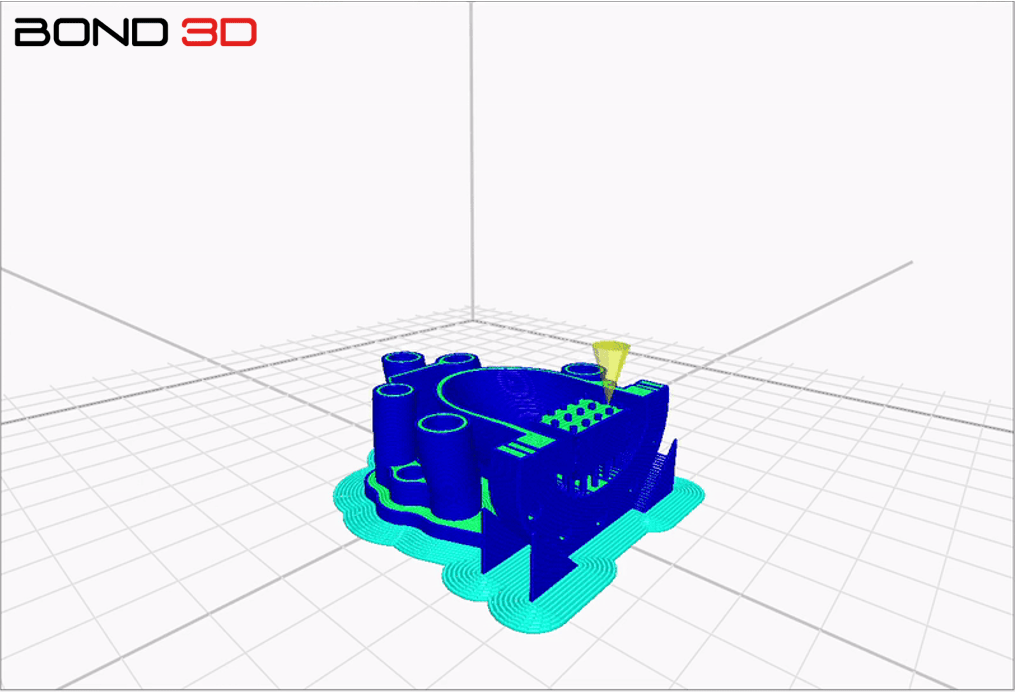

Bond3D in-house developed slicer software for PEEK

Bond3D developed its own slicer software to accommodate for our unique technology, pressure-controlled printing. Which makes it possible to make leaktight and isotropic strong PEEK parts. Another very important feature of our slicer software is to compensate for the anisotropic shrinkage PEEK has, due to being a semi-crystaline polymer. By using this shrinkage compensation, we are able to print a part within the dimensions needed for your application.

Designs dedicated to PEEK

Designing for Perfectly Printed PEEK Products takes a different approach then regular FMD Printing. As one of the pioneers in 3D Printing with PEEK we have a deep understanding of the technical possibilities. Our team of designers and engineers can support you in creating the right parts for any industry.

We love to join you in your journey from initial concept design or if needed somewhere along in the process to production. Get in direct content with our designers and engineers to see how we can make your product better with 3D Printed Peek Parts.

ill the gap between these tracks completely.

Discover our solutions

And see our designs for your industry.